World's first PEFC project certification for an industrial building of this size

Mayr-Melnhof Holz has ambitious goals for the use of wood as a sustainable building material and is doing pioneering work at its Leoben site: The new cross-laminated timber plant, currently under construction, including a high-performance re-sorting and planning plant as well as a fully automated high-bay warehouse for the storage of sawn timber, has become the world's first industrial building complex of this size to receive a PEFC project certificate.

PEFC - Confirmed sustainability

Mayr-Melnhof Holz has ambitious goals for the use of wood as a sustainable building material and is doing pioneering work at its Leoben site: The new cross-laminated timber plant, currently under construction, including a high-performance re-sorting and planning plant as well as a fully automated high-bay warehouse for the storage of sawn timber, has become the world's first industrial building complex of this size to receive a PEFC project certificate.

PEFC - Confirmed sustainability

All Mayr-Melnhof Holz sites and wood construction products are already PEFC-multisite certified (CoC - Chain of custody, Programme for the Endorsement of Forest Certification Schemes). Wood and timber products with the PEFC seal of approval originate from clearly documented, sustainable origins: controlled sources of supply, stable and long-standing partnerships with our suppliers, short transport routes, and the complete utilization of every tree trunk are the top priorities.

The principle of sustainability, which has been followed by the timber industry for 300 years, is a matter at Mayr-Melnhof Holz, of course. Therefore, what could be more obvious than to also apply for the corresponding certification for the new production halls at the Leoben site?

World premiere with exemplary function

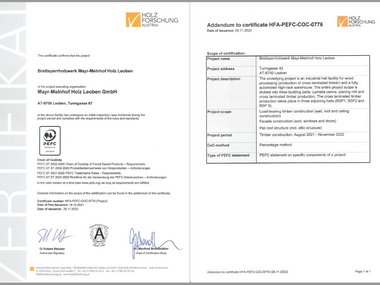

Mayr-Melnhof Holz received the world's first PEFC project certificate with the number HFA-PEFC-COC-0776 for an industrial building of this size. The new cross-laminated timber plant in Leoben with an upstream high-performance re-sorting and planing mill as well as a fully automated high-bay warehouse for the storage of sawn timber acts as an absolute showpiece for sustainable, ecological industrial hall construction worldwide. With its scope, the construction project sets a new international quality standard for future timber buildings of all sizes.

Joint effort for climate protection

The project scope for the certification of the new plant includes the load-bearing timber construction (wall, roof and ceiling construction), the facade construction (excluding windows and doors), as well as the flat roof construction (including attic construction). In total, more than 11,500 m³ of PEFC-certified timber elements are installed, produced at the locations of the Mayr-Melnhof Holz Group. In order to be able to ensure the certification of a construction project of this scope, the energetic cooperation of the construction companies as well as the company's own wood processing sites was necessary. Compliance with the strict PEFC guidelines is critically reviewed on a regular basis by Holzforschung Austria.

Joint effort for climate protection

The project scope for the certification of the new plant includes the load-bearing timber construction (wall, roof and ceiling construction), the facade construction (excluding windows and doors), as well as the flat roof construction (including attic construction). In total, more than 11,500 m³ of PEFC-certified timber elements are installed, produced at the locations of the Mayr-Melnhof Holz Group. In order to be able to ensure the certification of a construction project of this scope, the energetic cooperation of the construction companies as well as the company's own wood processing sites was necessary. Compliance with the strict PEFC guidelines is critically reviewed on a regular basis by Holzforschung Austria.

Timber construction: sustainable paths to the future

As a pioneering achievement, the PEFC certification of this construction project broadens the view of climate-friendly industrial hall construction of the future. Around 11,500 tons of CO2 are bound in the PEFC-certified timber used - approx. one ton per cubic meter of wood. This does not include wood products used for other areas, such as interior offices, visitor walkway, windows and doors, etc. Also not included are the avoided CO2 emissions due to the use of wooden construction elements instead of conventional building materials, which are much more CO2-intensive in production and transport to the construction site.

CEO Richard Stralz: "We regard sustainable management as our corporate responsibility at all levels. By carrying out the building project as a timber construction, we are making an important contribution to climate protection – and hope for numerous imitations."