A step towards automation in Leoben: High-bay sawn timber storage system

As part of the expansion of the Leoben site by a modern plant for the production of cross-laminated timber, investments are also being made in a high-bay warehouse for the sawn timber. In the future, the lumber packages with a wide range of dimensions will be provided automatically and with route accuracy for truck loading or the adjacent cross-laminated timber production.

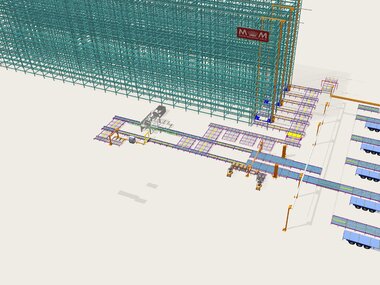

The future-oriented intralogistics solution consists of a fully automatic, 3-aisle high-bay warehouse, an innovative conveyor system, a fully automatic strapping and squared timber stacking system, a stretching system, stacking and labelling machines, and a modern truck loading system. In addition, intelligent warehouse management, plant control and plant visualisation are integrated and communicate with the internal ERP systems.

The sawn timber packages are received from the grading and planing plant, weight and contour are controlled and transported to the high-bay warehouse. There, they are automatically placed in temporary storage. To avoid empty runs, a sequence- and route-specific retrieval order is executed immediately.

The retrieved packages are automatically supported with squared lumber, strapped, and, if required by the customer, also wrapped and automatically labelled. At a robot station for truck loading, adjacent to the loading hall, up to four packages are stacked to a single stack; for packages without squared lumber, intermediate lumber can be inserted here for stacking by robot. The stacks are taken to one of five staging lanes by a distribution truck. There, a complete truck load is provided and loaded by means of a loading crane.

In the downstream zone of the high-bay warehouse, retrieval tables are provided in each rack aisle for internal transport. Here, the sawn timber packages required in the cross-laminated timber plant are retrieved and automatically fed to production via a distribution car.

The high-bay warehouse has 7,623 storage locations, and the storage and retrieval capacity is 62/71 packages per hour. With the construction of the fully automated high-bay warehouse, Mayr-Melnhof Holz is taking a further step towards modernisation and positioning itself for the future. The company has commissioned HÖRMANN Logistik with the realisation of the project. The construction is running at full steam, the commissioning is planned for December 2022.

Your media relations contact person

CONTACT